Heavy hammer type automatic pressure holding hydraulic control slow closing non-return butterfly valve

- Product Type : Check Valve

- Introduction : Hydraulic control slow closing butterfly valve is currently our company's more advanced pipeline control equipment, mainly installed in the hydropower station turbine inlet, used as turbine inlet valve; or installed in water conservancy, electricity, water supply and drainage and other types of pumping station pump outlet. Replace the function of check valve and gate valve. When working, the valve and the pipeline host are equipped with the platform. According to the principle of hydraulic transition process, through the preset opening and closing procedure, the water hammer in the pipeline is effectively removed, the reliable cut-off of the pipeline is realized, and the safety of the pipeline system is protected.

Product Details

1. Product Introduction

Hydraulic control slow closing butterfly valve is currently our company's more advanced pipeline control equipment, mainly installed in the hydropower station turbine inlet, used as turbine inlet valve; or installed in water conservancy, electricity, water supply and drainage and other types of pumping station pump outlet. Replace the function of check valve and gate valve. When working, the valve and the pipeline host are equipped with the platform. According to the principle of hydraulic transition process, through the preset opening and closing procedure, the water hammer in the pipeline is effectively removed, the reliable cut-off of the pipeline is realized, and the safety of the pipeline system is protected.

The hydraulic control slow closing butterfly valve produced by our company has small flow resistance coefficient, high degree of intelligence, complete functions, stable and reliable performance. It is a new generation of intelligent, high-efficiency and energy-saving products developed by our company's designers on the basis of extensive collection, research and summary of the performance of similar products at home and abroad. The company has strong technical force, and can be designed separately according to the special requirements of users, and meet the needs of users for such products in many ways.

The main features of the product are as follows;

1. It can replace the function of the original electric gate valve and check valve at the outlet of the water pump, and the machine, electricity and liquid system are integrated as a whole, reducing the floor space and infrastructure investment.

2. The electro-hydraulic control function is Qi Jin, which can be used as an independent system for local debugging and control without additional configuration. It can also be used as an equipment unit of the distributed control system (Dcs), which is centrally managed by the central computer through the l/0 channel and realizes linkage operation with water pumps, turbines, bypass valves and other pipeline equipment. It is also equipped with manual function, and can manually open and close valves when there is no power supply, meet the valve debugging and control requirements under special conditions.

3. Good controllability, large adjustment range and strong adaptability. The electro-hydraulic control system is equipped with multiple adjustment points, which can be set according to different pipeline control requirements for opening and closing procedures to ensure that when the conditions for opening and closing the valve are met, the valve can be opened and closed automatically according to the preset time and angle. Fast and slow two-stage closing. And can realize no electric shut-off valve, effectively eliminate the destructive water hammer, prevent the water pump and turbine runaway accidents, reduce the pressure fluctuation of the pipe network system, and ensure the safe and reliable operation of the equipment.

4. The main valve sealing pair is a three-eccentric metal seal or a double-eccentric rubber seal structure, which is easy to open and close and reliable in sealing: there is an additional increase in eccentricity, so that the valve has good self-closing and self-sealing performance. Medium and small diameter butterfly plates are designed as streamlined flat plate structure, and large diameter butterfly plates are designed as double flat plate frame structure. Smooth water flow. Valve flow resistance coefficient is small, energy saving effect is obvious.

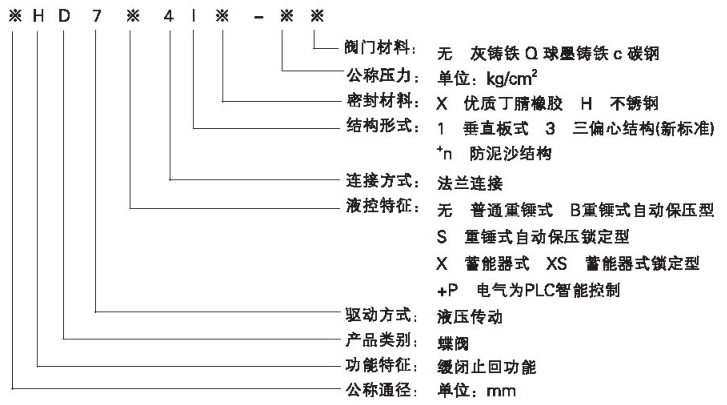

2. Model description

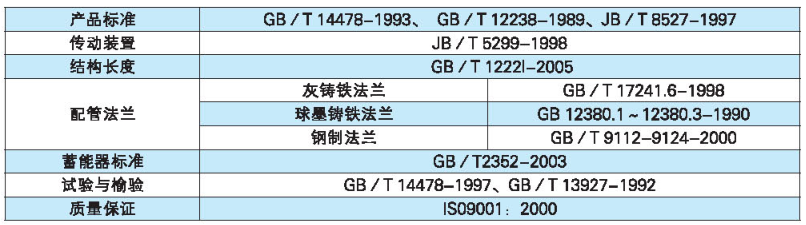

3.Standards and Specifications

Note: Other relevant standards and foreign standards may be adopted. Flange size can be manufactured according to user requirements, but should be stated in the order contract.

4.Basic parameters

Note: 1. 1Mpa-10.2kg/cm 2, when used in hydropower station, the sealing test pressure can be calculated according to the maximum static head of the power station.

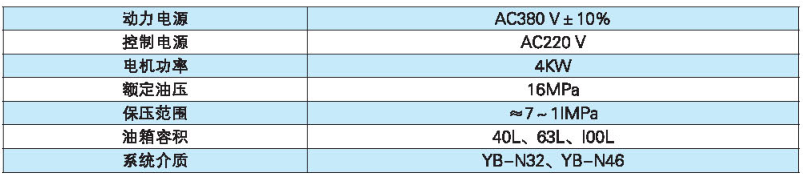

5.Electro-hydraulic control parameters

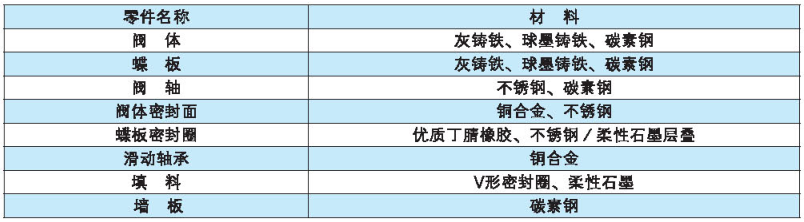

6.Selection of materials for main parts

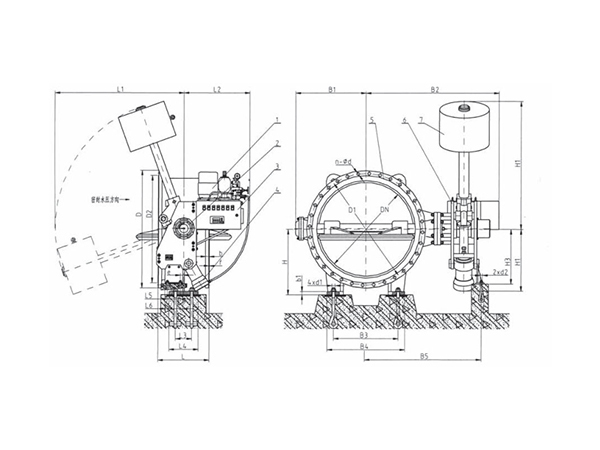

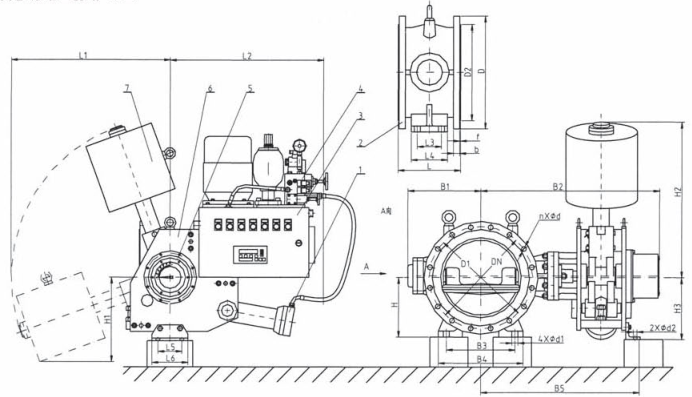

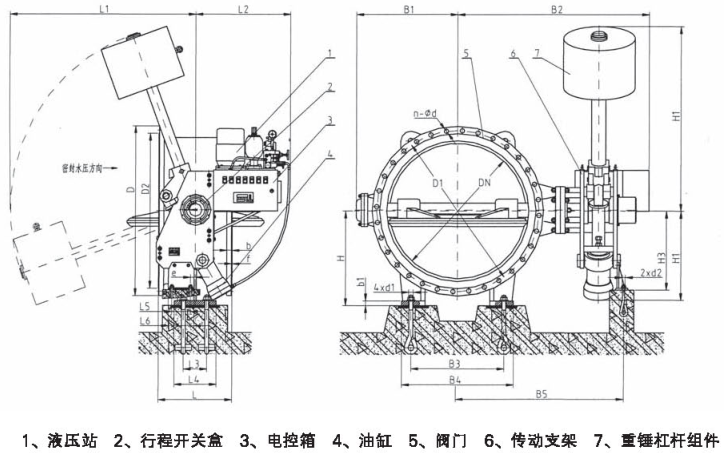

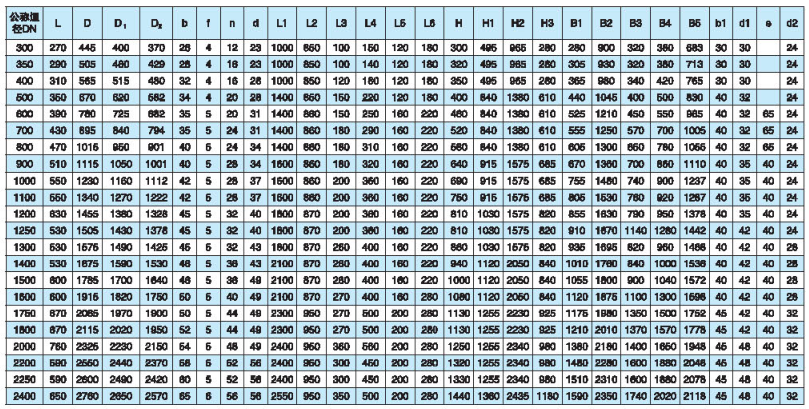

7.Outline and connection dimensions

Fig. 1 Shape and Connection Dimension of Heavy Hammer Type Automatic Pressure Holding Hydraulic Control Slow-closing Stop Butterfly Valve (DN≤ 500)

Fig. 2 Outline and connection dimension of automatic pressure-holding weight type hydraulic control slow-closing non-return butterfly valve (DN≥ 600)

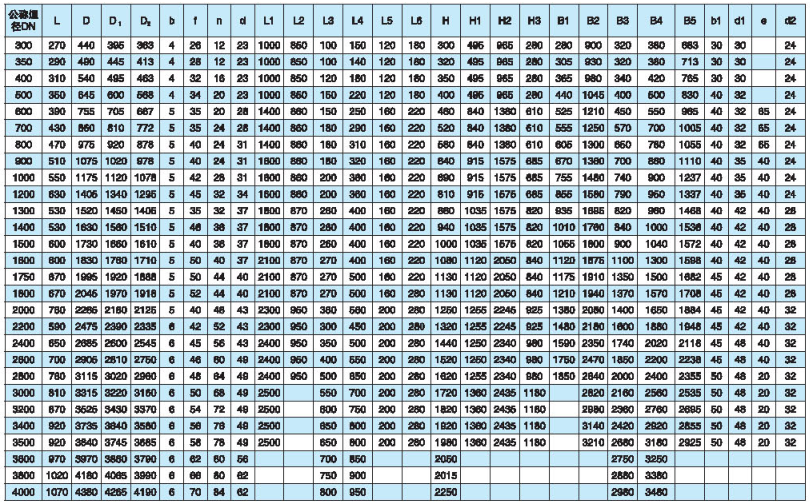

Main Appearance and Connection Dimension of Heavy Hammer Type Hydraulic Controlled Slow Closing Butterfly Valve (PN = 0.6Mpa) Unit: (mm)

Main Appearance and Connection Dimension of Heavy Hammer Type Hydraulic Controlled Slow-closing Butterfly Valve (PN = 1.OMpa) Unit: (mm)

Note: the valve structure length in the table is GB/T12221-2005; Where DN≤ 1200 is based on flange type long series 14,1200

Flange of PN4.0 shall be of concave-convex structure (MF) according to GB/T9113.2-2000, and other pressure levels shall be of convex structure (RF) according to GB/T9113.1-2000.