Fully welded filter ball valve

- Product Type : Ball valve

- Introduction : Integral welded ball valve, there will be no external leakage phenomenon. The valve seat is composed of carbonized Teflon sealing ring and spring, and has strong adaptability to pressure and temperature changes, and will not produce any leakage within the marked pressure and temperature range. The processing of the sphere is tracked and detected by an advanced computer detector, and the processing density of the sphere is high. The sealing ring is made of carbon C- PTFE with a content of 20 �rbon to ensure complete no leakage. The valve body is small, light in weight, beautiful in appearance and long in service life.

Product Details

Fully welded filter ball valve

Integral welded ball valve, there will be no external leakage phenomenon. The valve seat is composed of carbonized Teflon sealing ring and spring, and has strong adaptability to pressure and temperature changes, and will not produce any leakage within the marked pressure and temperature range. The processing of the sphere is tracked and detected by an advanced computer detector, and the processing density of the sphere is high. The sealing ring is made of carbon C- PTFE with a content of 20 �rbon to ensure complete no leakage. The valve body is small, light in weight, beautiful in appearance and long in service life.

Product Description

·Integral welded ball valve, there will be no external leakage phenomenon.

·The valve seat is composed of carbonized Teflon sealing ring and spring, and has strong adaptability to pressure and temperature changes, and will not produce any leakage within the marked pressure and temperature range. The processing of the sphere is tracked and detected by an advanced computer detector, and the processing density of the sphere is high.

·The sealing ring is made of carbon C- PTFE with a content of 20 �rbon to ensure complete no leakage. The valve body is small, light in weight, beautiful in appearance and long in service life.

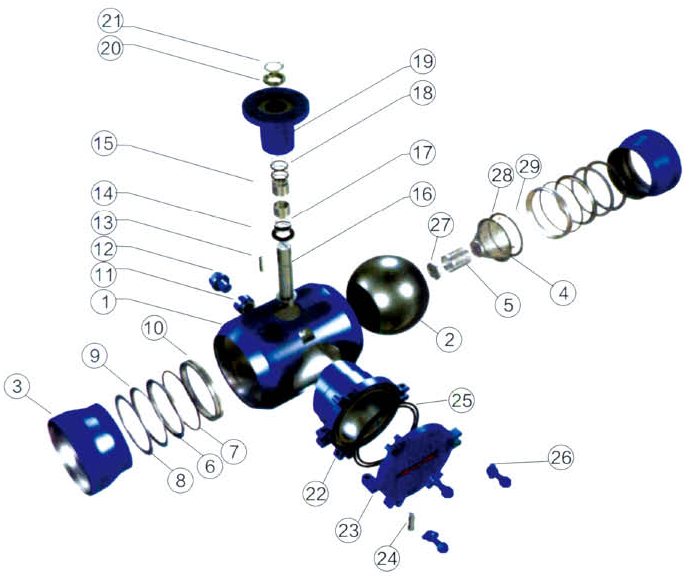

·The valve body, ball and side valve body are all formed by pressing with slotted steel pipe. The valve stem is sealed with double "O-ring" and has the function of preventing blowing out.

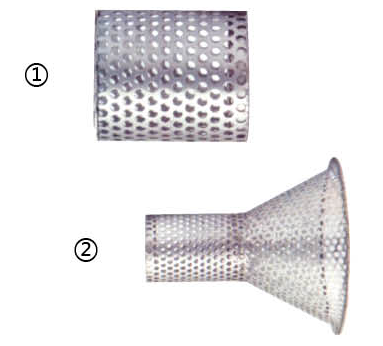

·The filter screen and the ball are integrated. The filter ball valve is connected to the pipeline and has a filtering function. It can be used instead of the filter, which has the effect of multiple uses of one valve, saves the installation space and operating cost of the pipeline, and can block impurities with a diameter greater than 4.5um from passing through.

·The filter screen is designed with a slope opening to ensure that the medium passes normally and the valve works normally under the condition of blocking impurity particles. Pressure relief valve design, adjustable valve inside and outside the pressure to improve the safety performance of the valve, while the use of threaded ball valve instead of pressure relief valve, the operation is more time-saving, labor-saving, convenient and flexible.

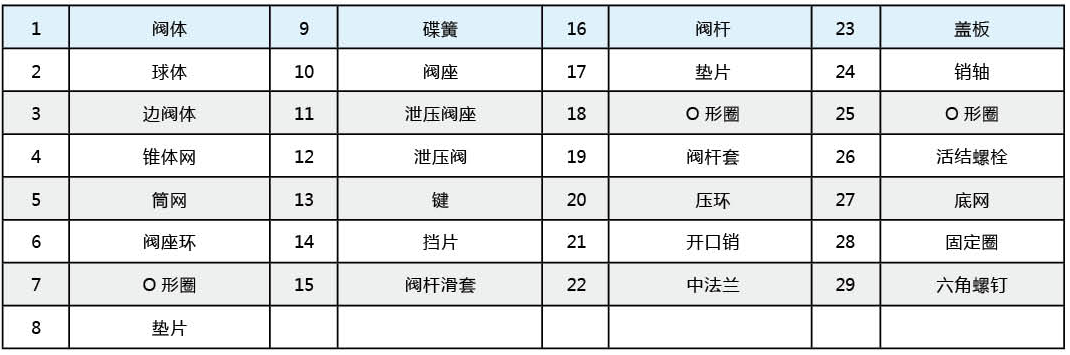

1. Traditional filter design

Impurity particles are cut off in the entire filter, the medium is seriously blocked, the heat loss is large, increase the pressure in the valve, reduce the service life of the valve.

2.ZQV slope mouth filter screen design

Slope mouth design, impurity particles are cut off at the bottom of the filter screen, the medium and slope mouth normal through, does not increase heat loss, does not generate internal pressure on the valve, does not reduce the service life of the valve.

3. Optional pressure relief and cleaning methods

The standard pressure relief configuration of the filter valve is a pressure relief valve structure, and a threaded ball valve can be used to replace the pressure relief valve.

4. Pressure relief valve design

When the valve is cleaned/maintained, the pressure in the valve body can be released through the pressure relief valve, and then the drain outlet is opened for cleaning/maintenance of the filter screen, which is very reliable.

5. Threaded ball valve design

Through the threaded ball valve to drain the pressure in the filter valve body. After the threaded ball valve is opened, release the pressure in the valve until there is no pressure, and use the air pressure pump to apply pressure to the side of the threaded ball valve to remove the dust and impurities in the filter screen.

6. Installation and use method

The arrow of the valve body points to the flow direction of the medium. Close the ball valve, open the loose knot bolt of the flange cover, and take out the filter screen to remove the impurities blocked.

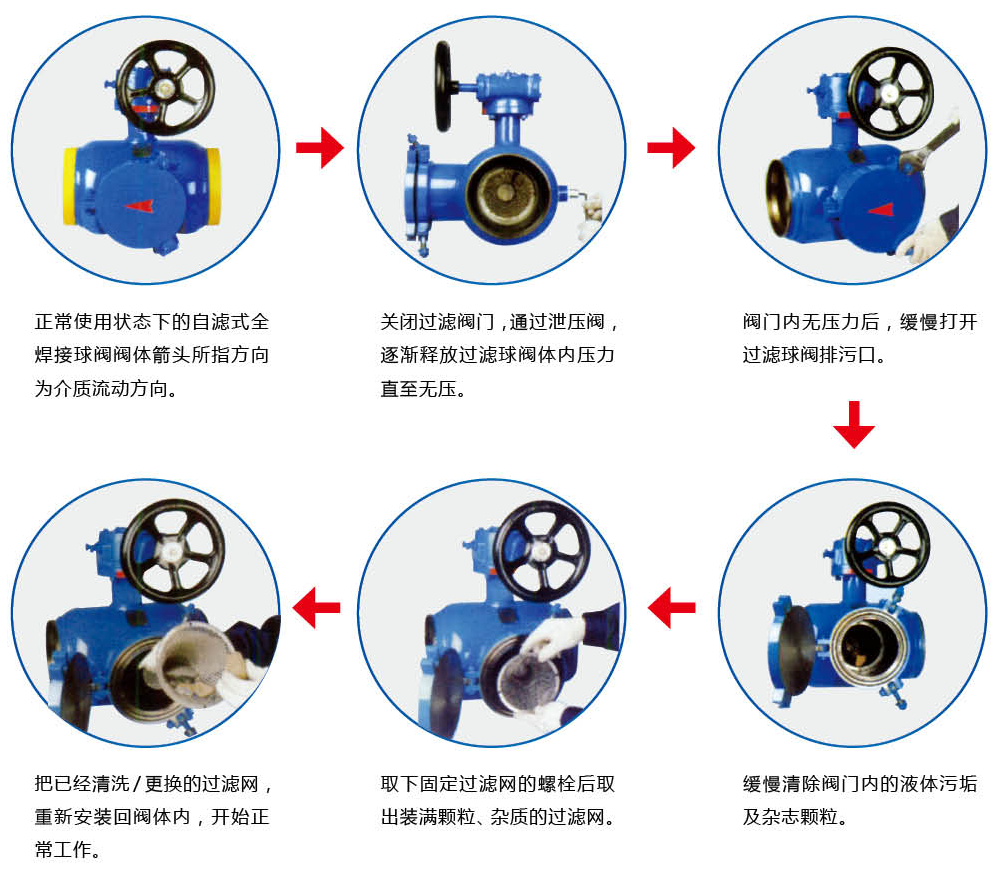

7. Cleaning process