CARX compound exhaust valve

- Product Type : Exhaust valve

- Introduction : CARx Composite Exhaust Valve The valve body is barrel-shaped, and the internal parts of the valve include stainless steel float ball, lever and disc. The valve is installed at the outlet of the pump or in the water distribution pipeline to exclude the air in the pipe to improve the efficiency of the pipeline and the water pump. When negative pressure is generated inside the tube-once. This valve quickly sucks in outside air to prevent damage to the pipeline due to negative pressure. Composite exhaust valve for the highest point on the pipeline or a closed place, the gas in the tube to clear the pipeline, to achieve normal work. If the exhaust valve is not installed, the liquid flowing in the pipe will generate dynamic heat and cause gas to form a short circuit, which will make the water outlet capacity of the pipe fail to meet the requirements. Secondly, the pipe will have negative pressure when the pipe is running and the pump will stop, which will cause the pipe to vibrate or rupture. The exhaust (suction) valve quickly sucks air into the pipe to prevent pipe vibration or rupture. Its working principle is: When the water injection in the pipe starts, the valve flap is in the open position to perform a large amount of exhaust. When the air is exhausted, the valve is filled with water, the float rises and drives the valve flap to close, and the exhaust is stopped. When the water in the pipe is transported normally. If a small amount of air collects in the valve to a considerable extent, the water level in the valve drops, and the air is discharged from the small hole. When the water pump stops, the water in the pipe is empty or negative pressure is generated in the pipe. At this time, the plug head is quickly opened to inhale air to ensure the safety of the pipeline. Medium temperature: 0-80 ℃.

Product Details

Product overview

CARx Composite Exhaust Valve The valve body is barrel-shaped, and the internal parts of the valve include stainless steel float ball, lever and disc. The valve is installed at the outlet of the pump or in the water distribution pipeline to exclude the air in the pipe to improve the efficiency of the pipeline and the water pump. When negative pressure is generated inside the tube-once. This valve quickly sucks in outside air to prevent damage to the pipeline due to negative pressure. Composite exhaust valve for the highest point on the pipeline or a closed place, the gas in the tube to clear the pipeline, to achieve normal work. If the exhaust valve is not installed, the liquid flowing in the pipe will generate dynamic heat and cause gas to form a short circuit, which will make the water outlet capacity of the pipe fail to meet the requirements. Secondly, the pipe will have negative pressure when the pipe is running and the pump will stop, which will cause the pipe to vibrate or rupture. The exhaust (suction) valve quickly sucks air into the pipe to prevent pipe vibration or rupture. Its working principle is: When the water injection in the pipe starts, the valve flap is in the open position to perform a large amount of exhaust. When the air is exhausted, the valve is filled with water, the float rises and drives the valve flap to close, and the exhaust is stopped. When the water in the pipe is transported normally. If a small amount of air collects in the valve to a considerable extent, the water level in the valve drops, and the air is discharged from the small hole. When the water pump stops, the water in the pipe is empty or negative pressure is generated in the pipe. At this time, the plug head is quickly opened to inhale air to ensure the safety of the pipeline. Medium temperature: 0-80 ℃.

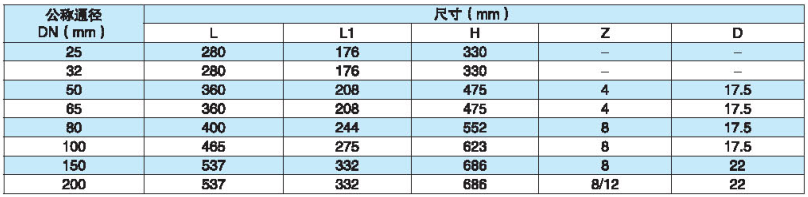

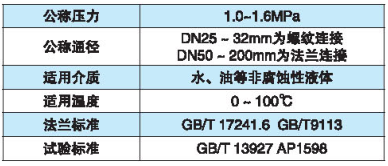

Main technical parameters

Main parts material

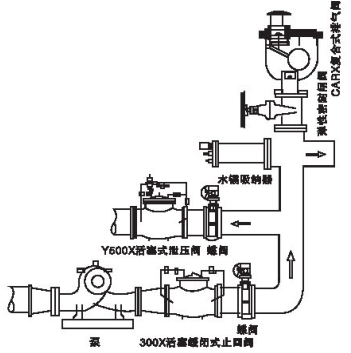

Installation Schematic

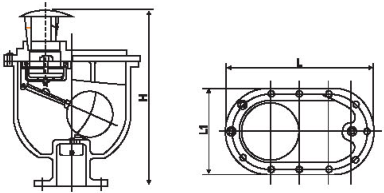

Outline and size of main connection