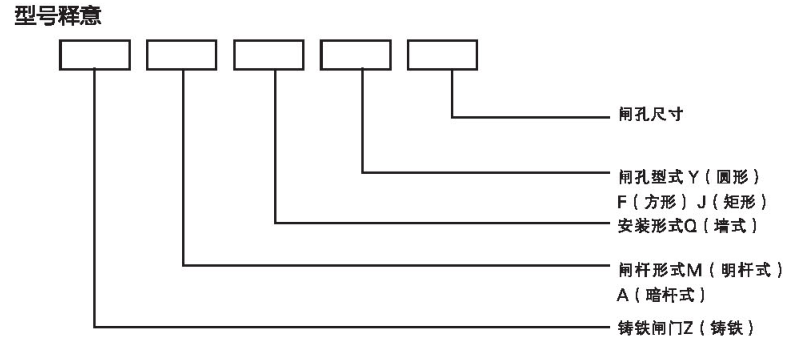

ZMQF type cast iron square gate

- Product Type : null

- Introduction : This product is widely used in urban water supply and drainage, metallurgy, petroleum, chemical, irrigation, electric power, textile and other industries on water treatment machine buildings to achieve flow and liquid level control, is one of the important equipment for water supply and drainage and sewage treatment.

Product Details

Product Introduction

This product is widely used in urban water supply and drainage, metallurgy, petroleum, chemical, irrigation, electric power, textile and other industries on water treatment machine buildings to achieve flow and liquid level control, is one of the important equipment for water supply and drainage and sewage treatment.

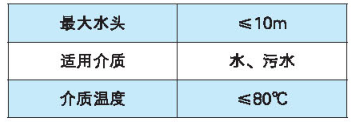

This product is suitable for the medium is water, medium temperature ≤ 80 ℃ maximum head ≤ 10m pipe mouth, sediment, sedimentation tank, diversion canal, pump station inlet and other places.

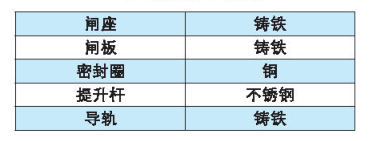

This product is mainly composed of a gate seat, a gate, a copper sealing ring, an adjusting embarrassing block, and a lifting part. Its structure is reasonable in design, good in sealing performance, strong in corrosion resistance, long in service life, convenient in installation, and easy to open and close. The structure is square, rectangular, round, and can be opened and closed manually or electrically.

Material of main components

Performance parameters

Installation Instructions

Before installation, the construction personnel must first clarify the construction drawings and be familiar with the installation dimensions and technical requirements of each part before construction. The installation must ensure that:

1. The center line of the gate coincides with the center line of the gate hole, and the maximum allowable displacement is ≤ 15mm.

2. The water stop plane of the gate shall be located on the same vertical plane and parallel to the installation plane, and the inclination angle between the vertical center line of the gate and the plumb line shall be ≤ 2.

Attention must be paid when installing the gate

1. When the brake rod is too long, the brake rod support shall be set to prevent the brake rod from buckling and instability during the opening and closing process, and to ensure the safe opening and closing of the gate.

2 When the gate is installed, the guide rail surface of the gate groove shall be used as the reference for correction to ensure that the gate groove is vertical and no skew is allowed. The gate rod shall be vertically raised and lowered.

3. Before the goods arrive at the delivery place, the gate must be placed horizontally to prevent deformation caused by unilateral force and affect the water stop performance.

4. The gate plate and the gate frame are precisely matched and scraped before leaving the factory. In order to ensure the water stop performance, the gate and the brake frame shall not be mixed with the products of the same specification.

5. Before water supply, the gate must be installed together with the hoist at one time, and water shall be provided after the opening and closing of the gate is light and flexible in the air test. It is strictly forbidden to pass water only when the gate is installed without the hoist.

6. The embedded parts used for the installation of the gate shall be provided by the user.

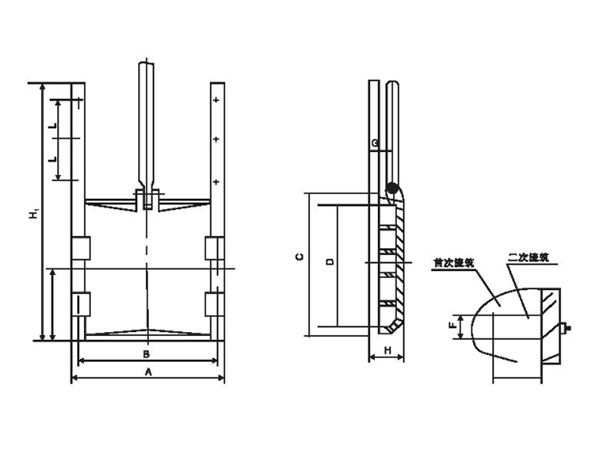

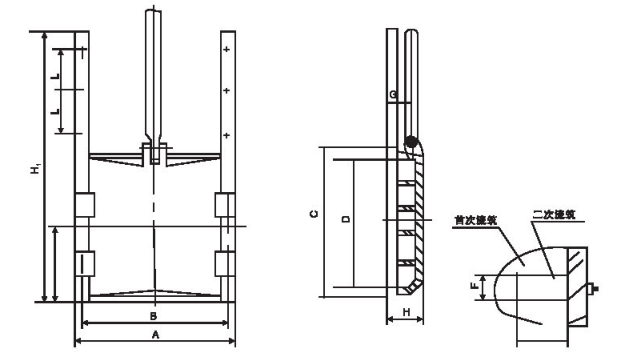

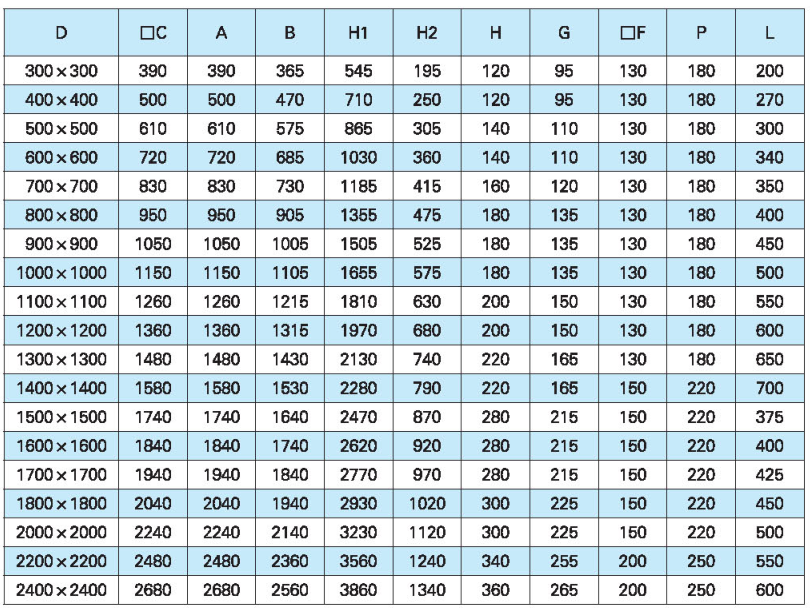

Shape and Connection Dimension of ZMQF300 × 300-2400 × 2400 Type Cast Iron Square Gate

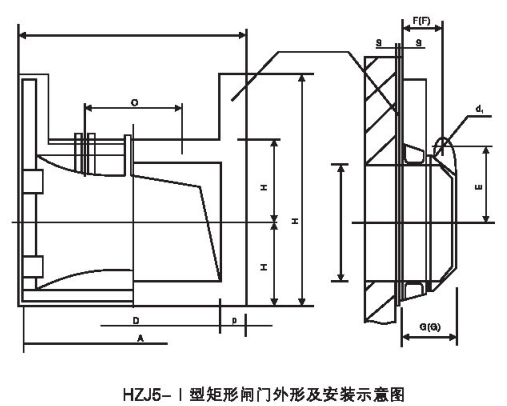

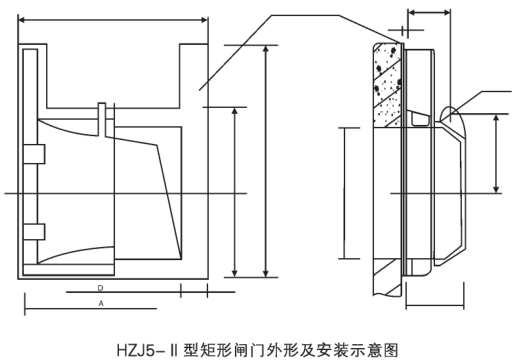

Shape and Installation Dimensions of HZJ5-Ⅰ Rectangular Gate

Note:

1. The recommend shall be installed with embedded steel plate type. The method is the same as that of square or round gate. It can also be installed with embedded bolts. The embedded steel plate shall be provided by the user. 2. For cast iron inlaid copper water stop structure, if the user does not require inlaid copper or its anti-corrosion material to be installed as water stop, the size in brackets in the chart shall be followed;

3. This valve is divided into two types: single lifting point and double lifting point. If double lifting point is required, please explain it when ordering, (Q = B/2);

4. When De2500, the horizontal embedded steel plate can be canceled;

5. The gate plate is of outer arc structure, and can also be made into flat plate structure, and its installation size is unchanged.

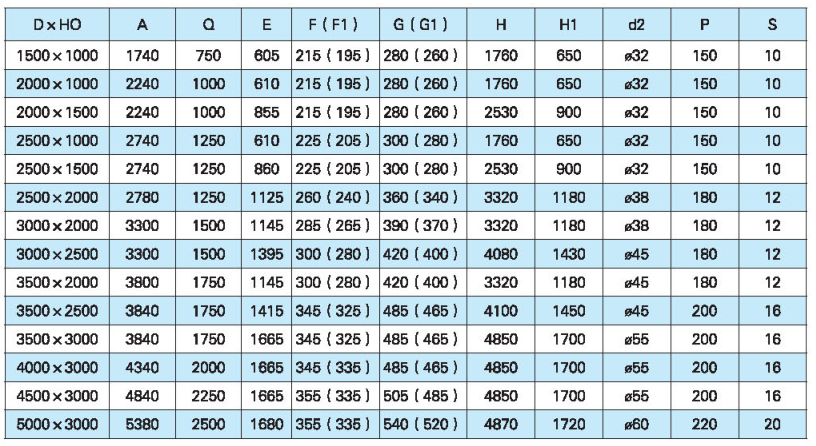

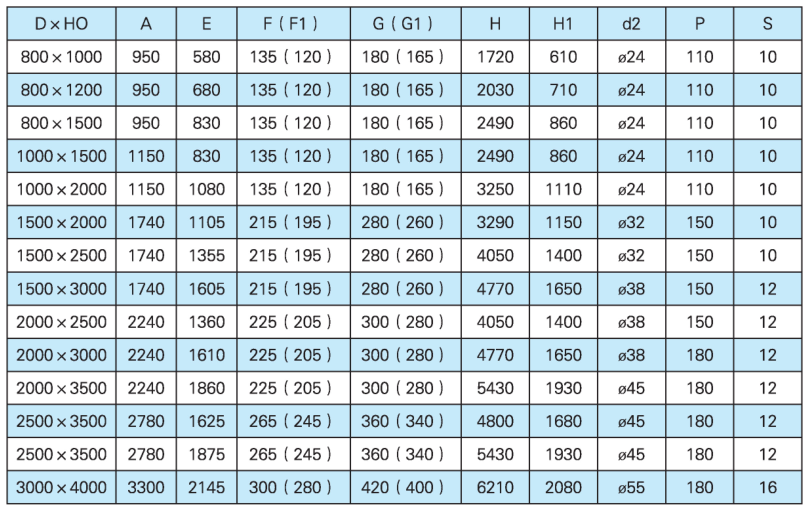

Table of Shape and Installation Dimensions of HZJ5-Ⅱ Rectangular Gate

Note:

1. The recommend shall be installed with embedded steel plate type in the same way as square or round gate, or with embedded bolt type. The embedded steel plate shall be provided by the user;

The cast iron inlaid copper sealing structure, such as the user does not require inlaid copper or its installation of anti-corrosion materials as a water stop, should be in accordance with the chart in brackets size;

3. When D≤ 2500, the horizontal embedded steel plate can be canceled;

4. The gate is of outer arc surface structure, and can also be made into flat plate structure, and its installation size is unchanged.