ZF Cone Valve (Energy-dissipation Valve)

- Product Type : Flow and pressure regulating valve

- Introduction : Cone valve is a suitable for high head, large flow conditions, no vibration, no cavitation operation, continuous discharge flow control of new valve products. Due to the use of inverted conical plunger spool named, referred to as the cone valve. Because of its excellent energy dissipation effect, it is also called energy dissipation valve. Cone valve in addition to the end of the channel is provided with a conical valve core, all the moving parts are set in the valve flow channel outside, so that the valve body internal flow is usually smooth, large flow and pressure drop loss is small, the entire working range will not produce cavitation and vibration, and in the small flow still has good flow control effect. The conical valve developed by our company has a fixed inverted conical structure. It is supported by hydraulic design and four guide wing blades used to reduce vibration. The flow rate is controlled by the front and back movement of the external movable casing. The valve body is respectively provided with metal-to-metal valve seats and supplementary soft sealing valve seats, which constitute a composite valve seat to ensure sealing performance. When discharged into the atmosphere, the water flow spreads at a wide cone angle and breaks down into a thin spray pattern, expending energy in the air. Usually according to the actual needs, can be required to control the water flow area, then install a different form of deflector at the outlet, which can not only mix the air with sufficient water, but also concentrate the flow. The results of the cone valve test showed no significant vibration, and the discharge coefficient was around 0.9 with or without the shroud when the fixed cone was fully open. ZF cone valve is mainly used in hydropower stations, reservoirs and urban water supply and drainage areas.

Product Details

ZF Cone Valve (Energy-dissipation Valve)

Cone valve is a suitable for high head, large flow conditions, no vibration, no cavitation operation, continuous discharge flow control of new valve products. Due to the use of inverted conical plunger spool named, referred to as the cone valve. Because of its excellent energy dissipation effect, it is also called energy dissipation valve. Cone valve in addition to the end of the channel is provided with a conical valve core, all the moving parts are set in the valve flow channel outside, so that the valve body internal flow is usually smooth, large flow and pressure drop loss is small, the entire working range will not produce cavitation and vibration, and in the small flow still has good flow control effect. The conical valve developed by our company has a fixed inverted conical structure. It is supported by hydraulic design and four guide wing blades used to reduce vibration. The flow rate is controlled by the front and back movement of the external movable casing. The valve body is respectively provided with metal-to-metal valve seats and supplementary soft sealing valve seats, which constitute a composite valve seat to ensure sealing performance. When discharged into the atmosphere, the water flow spreads at a wide cone angle and breaks down into a thin spray pattern, expending energy in the air. Usually according to the actual needs, can be required to control the water flow area, then install a different form of deflector at the outlet, which can not only mix the air with sufficient water, but also concentrate the flow. The results of the cone valve test showed no significant vibration, and the discharge coefficient was around 0.9 with or without the shroud when the fixed cone was fully open. ZF cone valve is mainly used in hydropower stations, reservoirs and urban water supply and drainage areas.

1. Product Overview

Cone valve is a suitable for high head, large flow conditions, no vibration, no cavitation operation, continuous discharge flow control of new valve products. Due to the use of inverted conical plunger spool named, referred to as the cone valve. Because of its excellent energy dissipation effect, it is also called energy dissipation valve.

Cone valve in addition to the end of the channel is provided with a conical valve core, all the moving parts are set in the valve flow channel outside, so that the valve body internal flow is usually smooth, large flow and pressure drop loss is small, the entire working range will not produce cavitation and vibration, and in the small flow still has good flow control effect.

The conical valve developed by our company has a fixed inverted conical structure. It is supported by hydraulic design and four guide wing blades used to reduce vibration. The flow rate is controlled by the front and back movement of the external movable casing. The valve body is respectively provided with metal-to-metal valve seats and supplementary soft sealing valve seats, which constitute a composite valve seat to ensure sealing performance. When discharged into the atmosphere, the water flow spreads at a wide cone angle and breaks down into a thin spray pattern, expending energy in the air. Usually according to the actual needs, can be required to control the water flow area, then install a different form of deflector at the outlet, which can not only mix the air with sufficient water, but also concentrate the flow. The results of the cone valve test showed no significant vibration, and the discharge coefficient was around 0.9 with or without the shroud when the fixed cone was fully open.

ZF cone valve is mainly used in hydropower stations, reservoirs and urban water supply and drainage areas.

2. Structure type

1, the cone valve through the actuator to drive the outer sleeve to achieve the opening or closing of the cone valve. Coated barrel cone valve is also divided into two types of tilt and horizontal.

2. Cone valve is composed of valve body, sleeve, actuator, connecting pipe and other parts.

3. Actuators have screw type, hydraulic type, electric push rod type and other types.

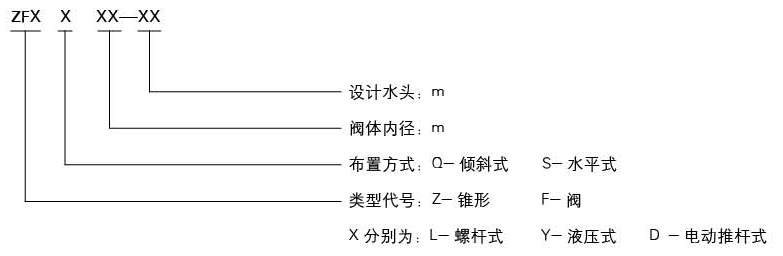

4. Cone valve model representation method:

(This labeling method adopts the SL498-2010 on Parameters, Types and Technical Conditions of Cone Valves for Labeling in the People's Republic of China Water Conservancy Industry, 2010-11-20)

Callout example:

ZFLQ1.0-60: The inner diameter of the valve body is 1.0m, the design head is 60m, and the inclined cone valve is opened and closed by screw.

ZFYS2.2-40: The inner diameter of the valve body is 2.2m, the design head is 40m, and the horizontal cone valve is opened and closed by hydraulic pressure.

3. Structure principle

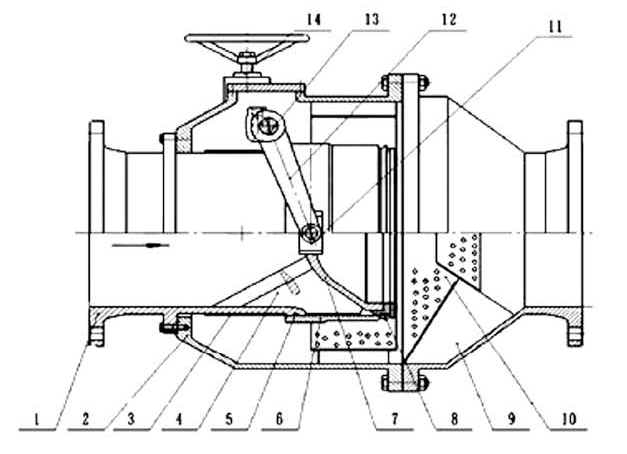

1. The structure and working principle of fixed cone valve

The structure diagram of fixed cone valve is as follows:

1. Nozzle 2. Valve body 3. Guide rail 4. Vane 5. Seal ring 6. Sleeve gate 7. Cone 8. Valve seat

9. Rear valve body 10. Guide shroud 11. Slide 12. Rocker arm 13. Valve shaft 14. Drive head

2. Performance characteristics of fixed cone valve:

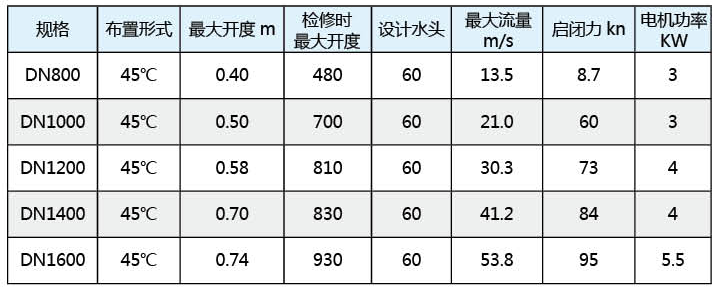

3. Main technical parameters and performance characteristics

Body material: carbon steel, stainless steel; nominal pressure PN:0.6~4.0MPa; nominal diameter DN:200~3000mm; strength test: PN× 1.5;

Sealing test: PN× 1.1; using temperature T:0~70 ℃; connection form: flange, welding; applicable medium: water, sewage;

4. Main technical parameters and performance characteristics

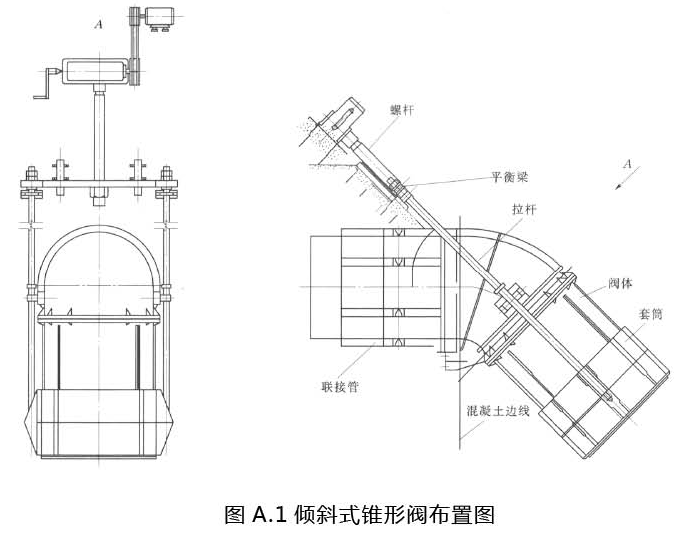

5. See Fig. A.1 for layout of inclined cone valve

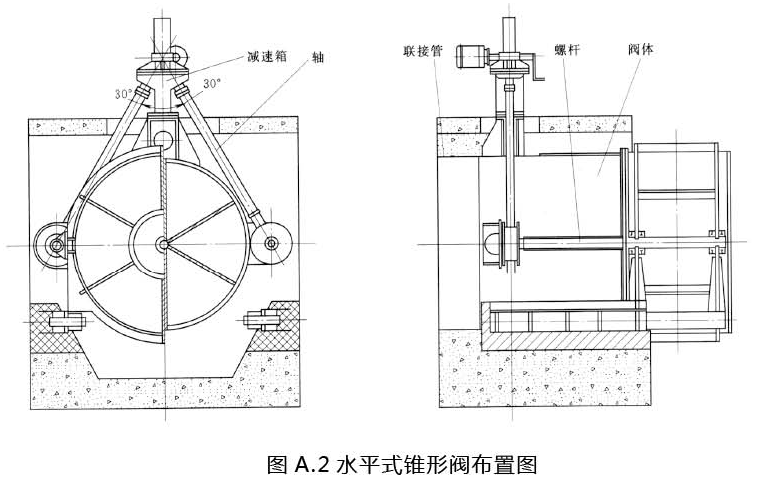

6. Horizontal cone valve layout is shown in Fig. A.2

7. Water Conservancy Cone Valve Use Characteristics

Cone valve can be roughly divided into buried pipe (over the transition tube) conical valve body, casing, actuator, pull rod and transmission mechanism and other parts. The valve body is fixed, and the actuator can open and close the movable outer sleeve through the transmission mechanism to achieve the opening and closing of the valve body.

Cone valve has the following advantages

Good hydraulic conditions, with a higher flow coefficient than other valves in our company u = 0.75-0.83 or higher;

Simple structure and light weight; all transmission parts are arranged outside the valve body, which is clear at a glance and easy to maintain and repair;

The opening and closing force is small, the operation is light, and it can be applied to small and medium-sized water conservancy projects without power supply. The opening and closing structure of electric, gas and hydraulic operation can be set up to easily realize remote control or unattended automatic operation;

When discharging, the spouting water tongue is trumpet-shaped, which is diffused and aerated in the air, and has good energy dissipation effect. Simple energy dissipation pool or no energy dissipation measures are needed. If it is set to submerged outflow, the underwater energy dissipation is also very simple;

The fluid is evenly divided by the internal 4 guide wings without vortex and vibration;

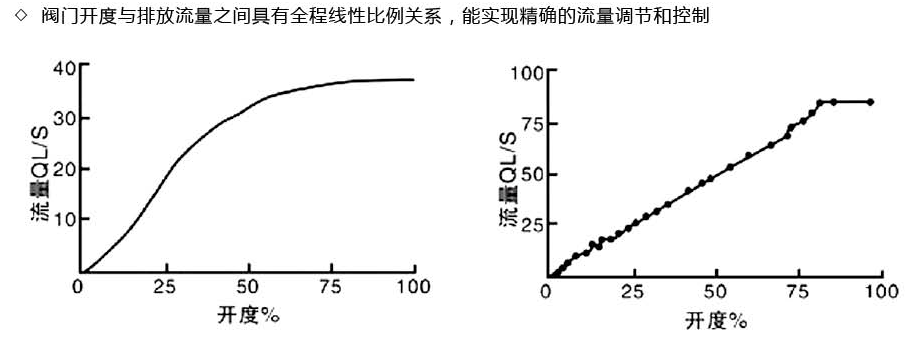

The opening and closing of the valve or flow control by the external casing up and down to drive the action of the conical valve core to achieve control, between the sleeve and the valve body through the guide ring and О ring to achieve guidance and sealing, so that the valve flow coefficient and valve opening have a certain proportional relationship;

For different conditions and pressure of the fluid medium, you can set the metal hard seal and plastic soft seal. The composite sealing structure designed with high-strength alloy stainless steel wear-resistant valve seat has the characteristics of metal-to-metal hard seal and soft seal;

The divergence angle can be limited, so that the fluid is decomposed into thin spray state or annular convection to achieve the purpose of impact offset. At the same time to adapt to the needs of different sites.

According to the angle between the horizontal line and the central axis of the valve, it is common to install it horizontally at 180 °. In addition, the methods used are 45 °, 60 ° and 90 °;

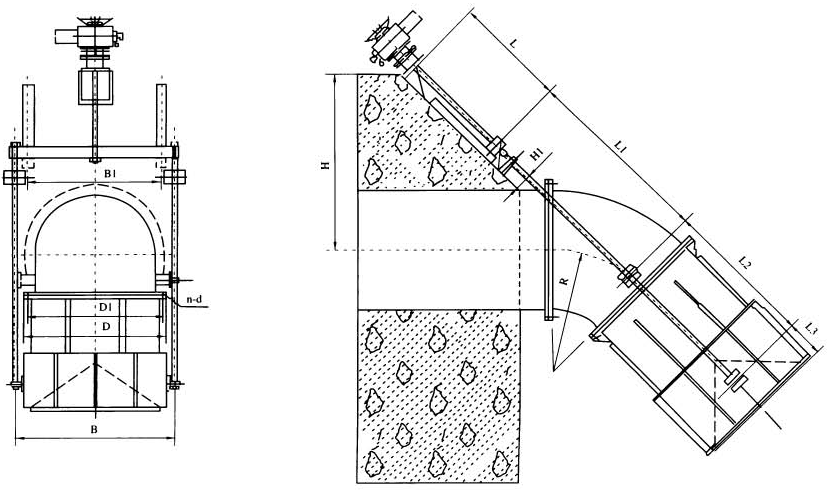

6.ZFL type cone valve main shape and connection size table (enterprise standard)

7.Main reference dimensions