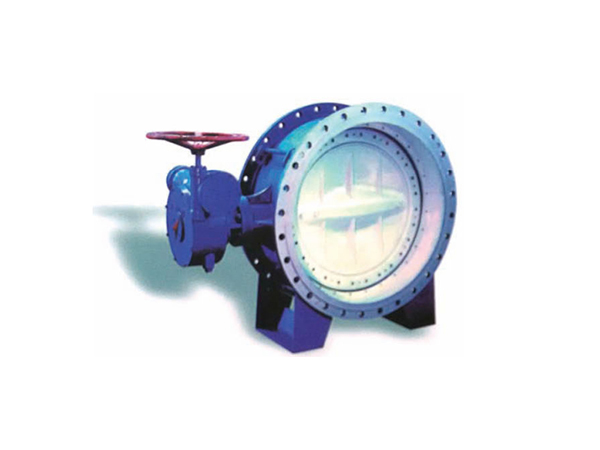

Sediment-proof type flanged butterfly valve

- Product Type : Butterfly valve

- Introduction : Sediment-proof butterfly valve is a new product developed by our company on the basis of double eccentric flanged butterfly valve, which is aimed at the problems of easy failure of valve axial seal and short applicable life for pipeline system with large sediment. Features: 1, the butterfly valve has the advantages of double eccentric flange butterfly valve. 2, the use of anti-sediment sealing structure, to ensure that the axial non-seepage, no corrosion, no stuck dead and other phenomena, to extend the service life of the valve.

Product Details

Sediment-proof type flanged butterfly valve

Overview: Sediment-proof butterfly valve is a new product developed by our company on the basis of double eccentric flanged butterfly valve for technological innovation and development, aiming at the problems of easy failure of axial seal of valve and short applicable life for pipeline system with large sediment. Features: 1, the butterfly valve has the advantages of double eccentric flange butterfly valve. 2, the use of anti-sediment sealing structure, to ensure that the axial non-seepage, no corrosion, no stuck dead and other phenomena, to extend the service life of the valve.

Overview

Sediment-proof butterfly valve is a new product developed by our company on the basis of double eccentric flanged butterfly valve, which is aimed at the problems of easy failure of valve axial seal and short applicable life for pipeline system with large sediment.

Features

1. The butterfly valve has the advantages of double eccentric flange butterfly valve.

2, the use of anti-sediment sealing structure, to ensure that the axial non-seepage, no corrosion, no stuck dead and other phenomena, to extend the service life of the valve.

Scope of application

This series of butterfly valves are widely used in metallurgy, chemical industry, petroleum, food, medicine, textile, papermaking, ship power, water supply and drainage and other corrosive and non-corrosive media pipelines, as a cut-off and throttling. It is more suitable for the pipeline of the irrigation station in the Yellow River basin with high sediment content.

Executive standards

Design: GB /T12238-2008

Flange connection: GB/T17241.6-2008, GB/T9115 (or according to user requirements)

Structure length: GB /T12221-2005

Pressure test: GB /T13927-2008

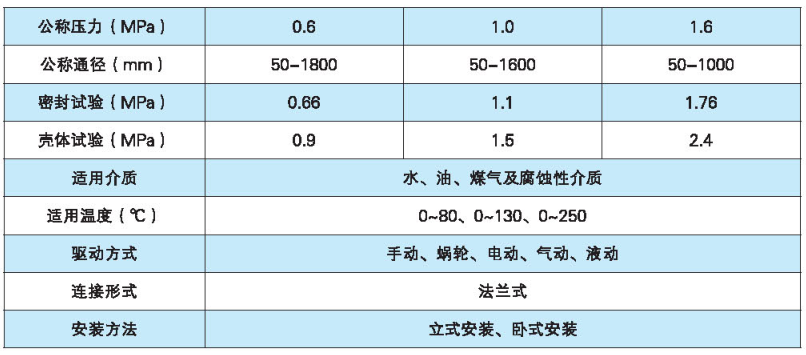

Main technical performance parameters

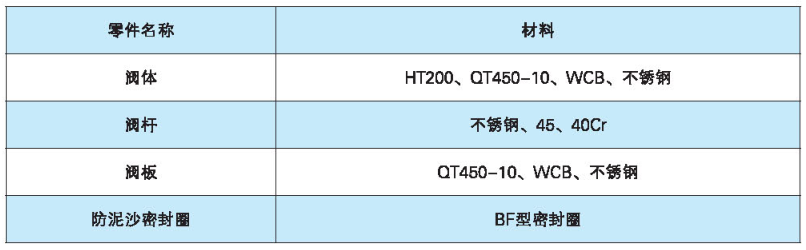

Material of main components

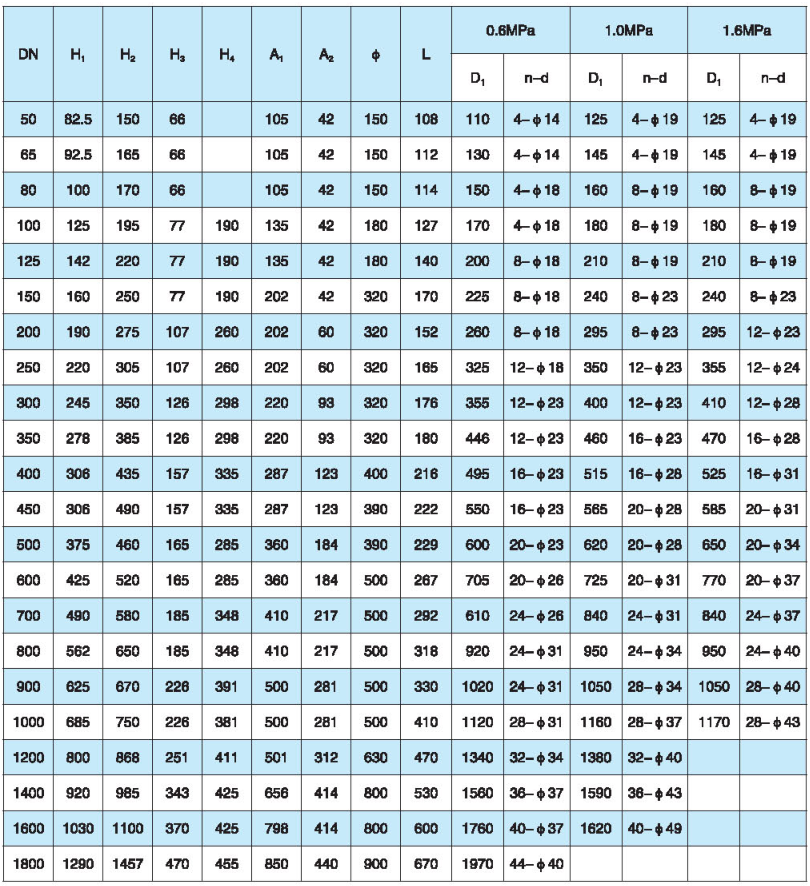

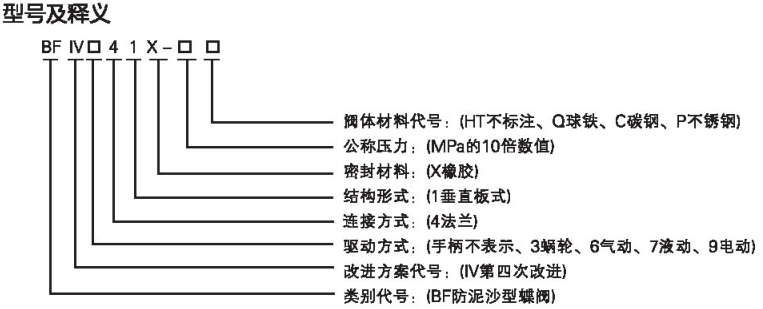

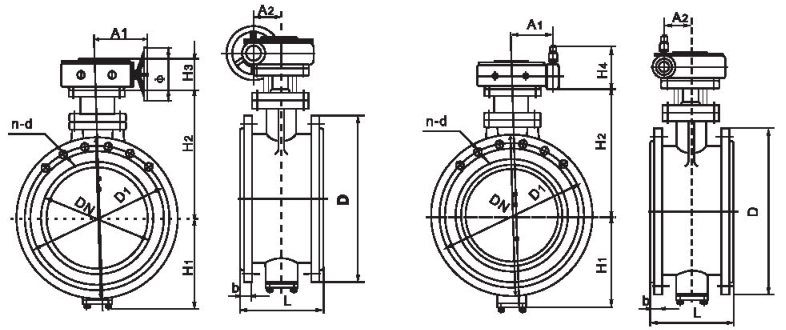

BFIV 341X-6/10/16 worm gear drive anti-sediment butterfly valve shape and connection dimensions